For universal application

- Reduced diversity of types As our solid carbide milling cutters are suitable for universal application and on a variety of materials, you will be able to benefit from higher flexibility.

- High productivity and process security Maximum performance combined with low vibration of the tools as the geometries are specifically designed for the various applications, irregular helix and pitch of the helix.

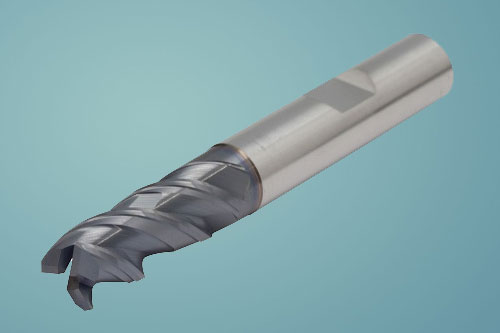

For steel machining

- High metal removal rates Thanks to the optimised cutting edge geometry, chip flute design and irregular helix, our solid carbide milling cutters for steel machining achieve high metal removal rates combined with reduced vibration and low cutting forces. As a result, the machine is only subject to minimal stress.

For the machining of stainless steel

- Optimised machining operation as a result of high end tools The geometries and grades of our solid carbide milling cutters are specifically adapted to the requirements of machining stainless steels and heat-resistant materials - this enables you to achieve optimal results.

- Productivity through intelligent design Our solid carbide milling cutters stand out amidst global competition through maximum cutting performance: the particularly developed chip groove geometry enables chip evacuation without problems and increases productivity as a result.

For titanium and heat-resistant

- Reliable quality The tool geometries are specifically adapted for the machining of titanium and titanium alloys reducing resonant oscillation thus minimising vibration and enhancing the quality of the component.

- Long tool life The carbide grades, optimised for the machining of titanium and heat-resistant materials guarantee reduced cutting forces and very good wear resistance which leads to considerably longer tool life.

For hard materials

- High-performing grades for hard materials With an increase in cutting force by factor 10 and temperatures up to 500°C hard material machining makes particularly high demands on the cutting material. For dry machining of materials with a hardness of 50 to 62 HRC, we have developed a special carbide grade made of very fine tungsten carbide powder with a high cobalt content. In combination with the correct coating, clearly reduced wear and thus longer tool life is obtained as a result.

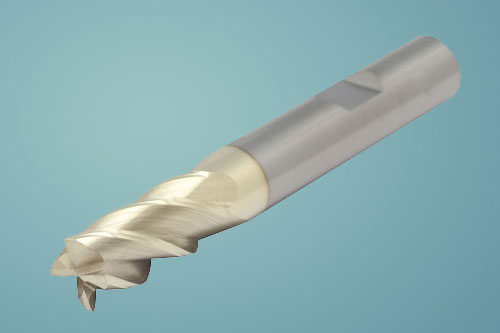

For aluminium machining

- Excellent surface quality Large polished chip flutes with special grades to ensure ideal chip evacuation and reduced edge build-up

- Maximum metal removal rate Thanks to their optimised geometries, our solid carbide milling cutters are suitable for the high-speed machining of aluminium and non-ferrous metals

For composite materials

- Great variety of products Our product range includes tooling with diverse cutting edge geometries, either uncoated or with diamond or DLC coating. Simply choose the right tool for your individual application.

- High component quality The specially cross-pitched peripheral cutting edge reduces splintering of the component which simultaneously leads to improved component quality and less non-conforming products.